Welcome to

Liquid Packaging Solutions, Inc.

Liquid Packaging Solutions, Inc. operates from 7am to 5pm CT, Monday through Friday. Contact us at 1-219-393-3600 for efficient and reliable packaging equipment, replacement parts, and technical service.

**Dock hours are from 8am to 2pm CT, Monday through Friday.**

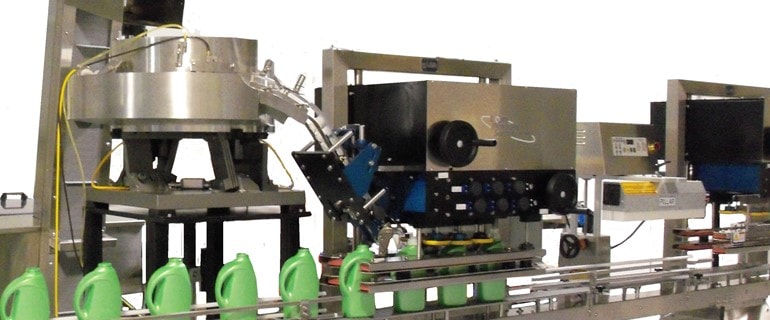

Discover solutions for your packaging project ranging from conveyors and turntables to rinsing equipment, filling machines, capping machines, and custom solutions for unique projects. Based in La Porte, Indiana, just an hour from Chicago, we specialize in designing, manufacturing, installing and servicing packaging machinery for diverse industries across the United States and around the world. Browse the categories of equipment to find the perfect packaging solution for your product or project, or call us today to speak with a Packaging Specialist for assistance in finding the right machinery. LPS looks forward to partnering with packagers of liquid products, providing not just the machinery, but the expertise, integration, installation and support liquid packagers need to succeed.

Rinsing Machines >

Rinsing Machines >

Filling Machines >

Filling Machines >

Capping Machines >

Capping Machines >

Conveyors >

Conveyors >