Capping Machines and Sealing Equipment

Work with LPS to find an efficient, consistent and reliable bottle capping machine for your packaging project.

At LPS, we build both semi-automatic and automatic bottle capping machines for a range of different closures in our LaPorte, Indiana plant, offering solutions for packagers large and small. Both chuck cappers and spindle capping machines are manufactured for continuous thread, screw-on type closures, including flat caps, flip-tops, pumps and trigger sprayers, among other variations. Our bartop corkers offer solutions for distillers, olive oil companies, wineries and any other packager that uses corks, T-corks or cork-like closures. ROPP cappers from LPS offer tamper evidence while often creating an aesthetically pleasing seal on a range of different products, while snap capping machines allow for different caps to be pressed into place with a tamp head or continuous pressure belt.

In addition to the bottle cappers manufacured by LPS, other cap sealing machinery can be built, or added, to complement the capping process, such as neck banders, capsule spinners, and cap delivery systems for automatic bottle cappers. For unique caps, closures, or projects, LPS can engineer custom solutions to meet your needs as well.

Discover the benefits of each cap sealing machine manufactured by Liquid Packaging Solutions below, or give us a call today to identify the best solution for your own project.

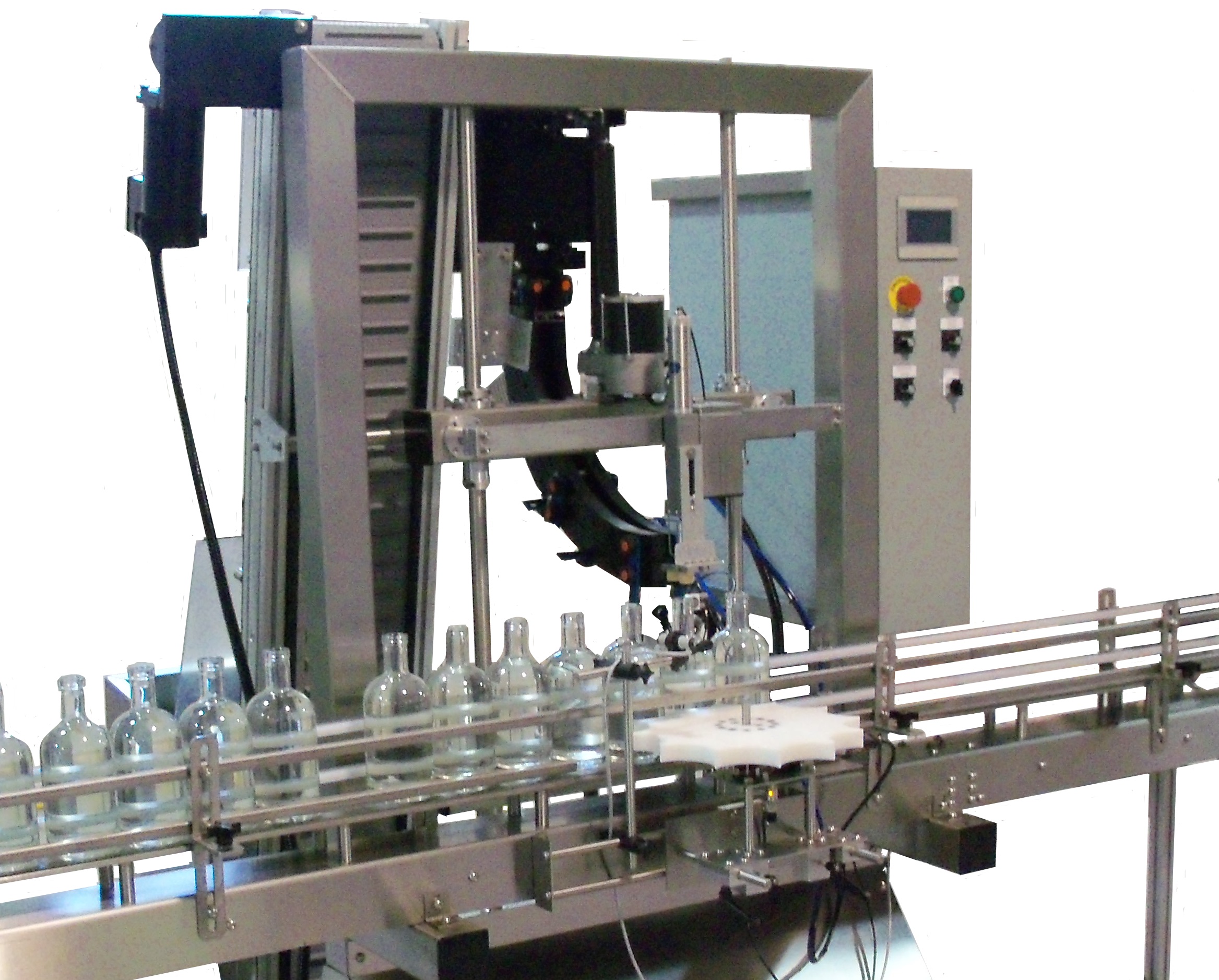

Efficiently tighten screw-on type threaded closures with a Spindle Capper from Liquid Packaging Solutions. The Spindle Capper, or retorquer, uses matched sets of rubber disks, or spindle wheels, that contact the cap to spin it tightly down on threads to seal the contain...

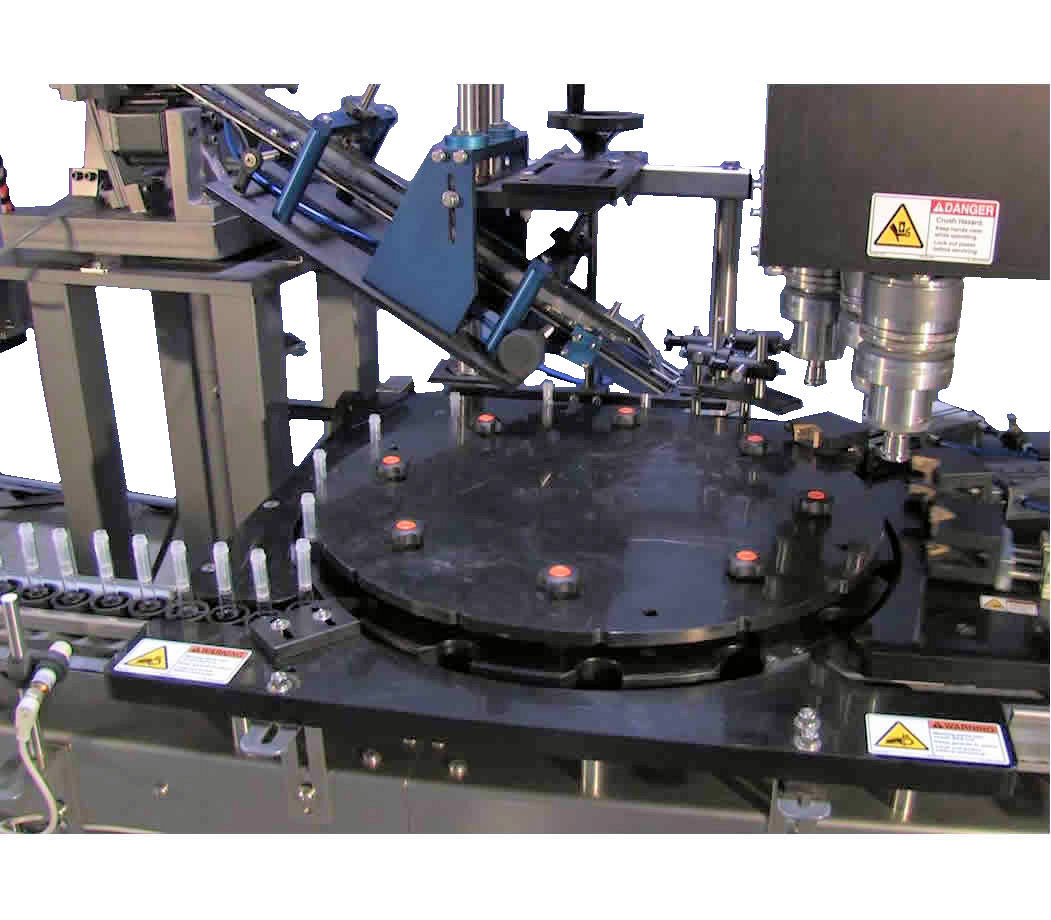

Consistently apply torque to screw-on type threaded caps with Chuck Cappers from Liquid Packaging Solutions. Chuck capping machines use a capping head, or chuck, often with an insert, to descend over a cap and bottle and apply torque to tighten screw-on, continuous thre...

Provide tamper evidence on a range of products using ROPP Cappers from Liquid Packaging Solutions. ROPP Cappers use capping heads that includes threading knives manufactured for the individual needs of the customer container. These machines provide a specialized s...

Find capping and sealing equipment for unique projects at Liquid Packaging Solutions. Custom capping projects require custom capping systems! Liquid Packaging Solutions manufactures capping machinery for unique caps, containers, and projects. Each specialty ...

Prevent leaks and provide tamper evidence with induction sealers offered by LPS. Induction sealers are used to provide tamper evidence on sealed products, prevent product leaks and provide long-lasting freshness to products. Food grade products and pharmaceutical ...

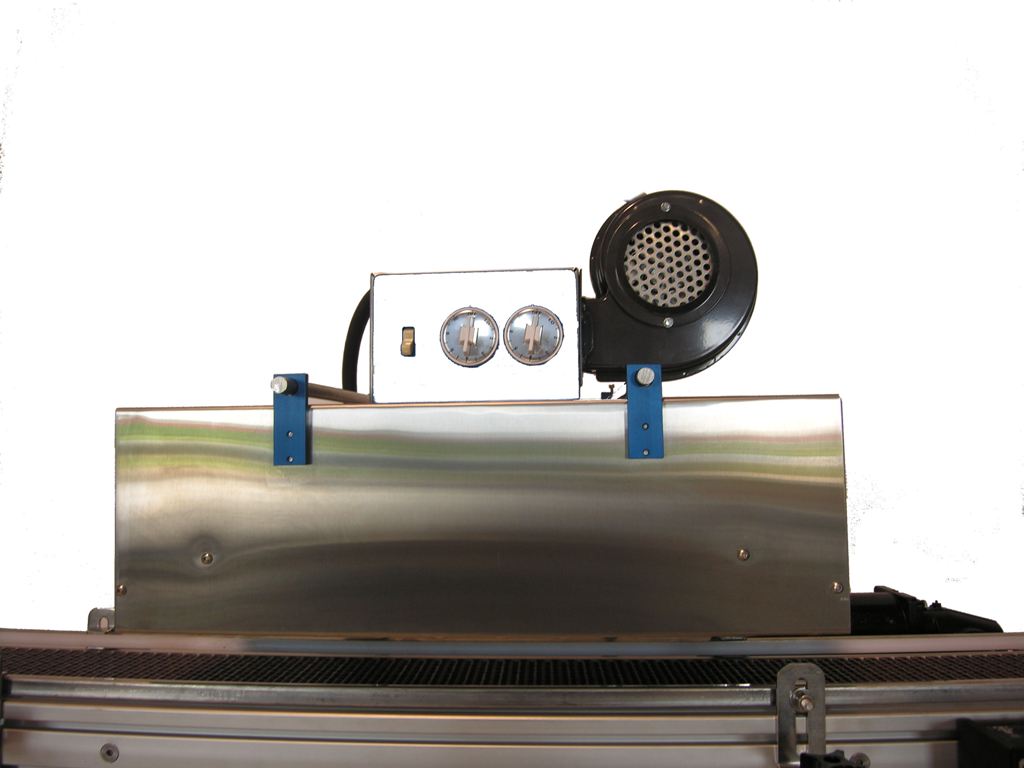

Apply shrink seals and sleeves efficiently and consistently with a Heat Tunnel from Liquid Packaging Solutions. Heat tunnels are used to apply shrink seals and sleeves to products in an efficient and consistent manner. These systems can be used by either manually ...

Combine neck banders and heat tunnels for an efficient sealing process. Neck Banders automatically strip a band from a roll and apply it to the cap and neck of a container. Heat tunnels, also offered by Liquid Packaging Solutions, are then used to shrink the band...

Provide tamper evidence for distilled spirits, wines, olive oils and more with a Capsule Spinner from LPS. The capsule spinner provides tamper evident seals for a range of products, though these machines are popular in industries such as distilled spirits, olive oils an...

Easily place and press corks, T-corks and similar closures with corking equipment from Liquid Packaging Solutions. Bottle corking machines provide a sealing system for cork-type closures that allow the corks to be securely pressed into bottles. Whether looking for...

Apply consistent pressure to efficiently seal containers with a Snap Capper from Liquid Packaging Solutions. Snap cappers use a press-on head or a belt to apply pressure to snap-on type closures and achieve a reliable seal. From chemicals to cosmetics, food and be...