Food and Beverage

From condiments, sauces, jams and jellies to the variety of bottled beverages on the market today, Liquid Packaging Solutions designs and builds the machinery that allows packagers to efficiently deliver Food & Beverage products to the consumer.

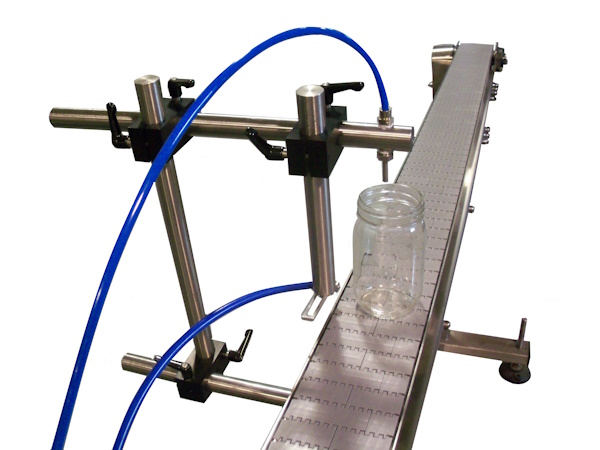

Container Cleaning Equipment

For consumable products such as food and beverage, protection against contamination is a must. Rinsing machines and bottle vacuums remove debris from the manufacturing, transit or storage of the containers to help ensure a pure product.

Filling Equipment

Food and beverage products can run the gamut on viscosity, from water-like beverages to thick sauces and pastes. LPS offers filling principles, including by volume, level or net weight, to efficiently fill any product viscosity.

Capping Machinery

With a multitude of products, the Food & Beverage Industry needs a variety of options for safely securing the product. LPS capping machines include options for screw-on closures, ROPP caps, snap-on tops, corks, and more.

Nitrogen Purge System

Nitrogen purge systems can be used to remove oxygen from the headspace of bottles to protect against oxidation. Using these simple machines between filling and capping can help to prolong shelf life without affecting the taste, color, or texture of products.

With both semi-automatic and automatic options, our equipment is built to meet the specific needs of each packager of foods and beverages. Discover a sampling of the most common equipment used in the industry below or give LPS a call to design the ideal system for your own project!

1-219-393-3600

Click here for full line Food & Beverage Systems!

Repeatedly and consistently tighten screw-on closures with the Automatic Spindle Capper manufactured by Liquid Packaging Solutions. With an automatic delivery system to present closures to each bottle, this capping machine for bottles using continuous thread caps ...

The Nitrogen Purge System from Liquid Packaging Solutions displaces oxygen from a container or container head space to extend product shelf life while also preserving taste, texture and color. Typically mounted to the conveyor between the filling and capping machi...

For free-flowing liquids, Automatic Gravity Fillers from Liquid Packaging Solutions provide a consistent, time-based volumetric fill for up to sixteen containers per cycle. Our gravity fillers use a raised tank and individually timed fill heads to allow for an accurate ...

Create an efficient and continuous bottle cleaning process with the Automatic Inverting Air Rinsing Machine from Liquid Packaging Solutions. With two to sixteen rinse heads, this machine clamps and inverts containers over an easily cleanable rinse basin before rem...

Though ideal for high viscosity liquids, semi-solids and products with particulates, Automatic Piston Fillers manufactured with up to 12 fill heads can fill liquids both thick and thin. Using a piston that never changes volume, these machines offer a highly accura...

The Automatic Net Weight Filling Machine offers an alternative to filling by volume or to a level. Using a scale for each fill nozzle, this machine offers packagers a way to fill containers accurately and efficiently by net weight. Net weight filling equipment all...

The full frame construction of the Semi-Automatic Overflow Filler from Liquid Packaging Solutions allows packagers to fill up to sixteen bottles to the same level each cycle with operator assistance. Operators will place bottles, initiate the fill cycle, and remove bott...

The space-saving Semi-Automatic Air Rinsing Machine from Liquid Packaging Solutions allows an operator to rinse between one and six bottles every rinse cycle. The operator of this LPS bottle cleaner places containers on the rinse nozzles, activates the rinse, and ...

Tabletop Piston Fillers from Liquid Packaging Solutions can be manufactured with one or two fill nozzles for a highly accurate fill by volume. Though able to handle a range of viscosities, piston fillers are ideally suited for thick products and semi-solids, inclu...