Pharma and Nutraceuticals

Pharmaceutical and nutraceutical products may include items such as eye drops, cough medicine, vitamins and liquid drugs. The key to packaging pharmaceutical and nutraceutical products is the sanitary design of the packaging system. Several alternatives are available to ensure that the product pathway, and the product itself, does not become contaminated during the filling and packaging process.

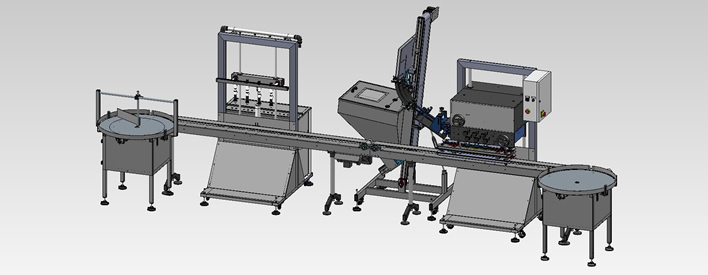

A typical pharmaceutical or nutraceutical packaging system is shown below:

This system includes:

- An overflow filler for free flowing products;

- A stainless steel spindle capper for continuous product capping;

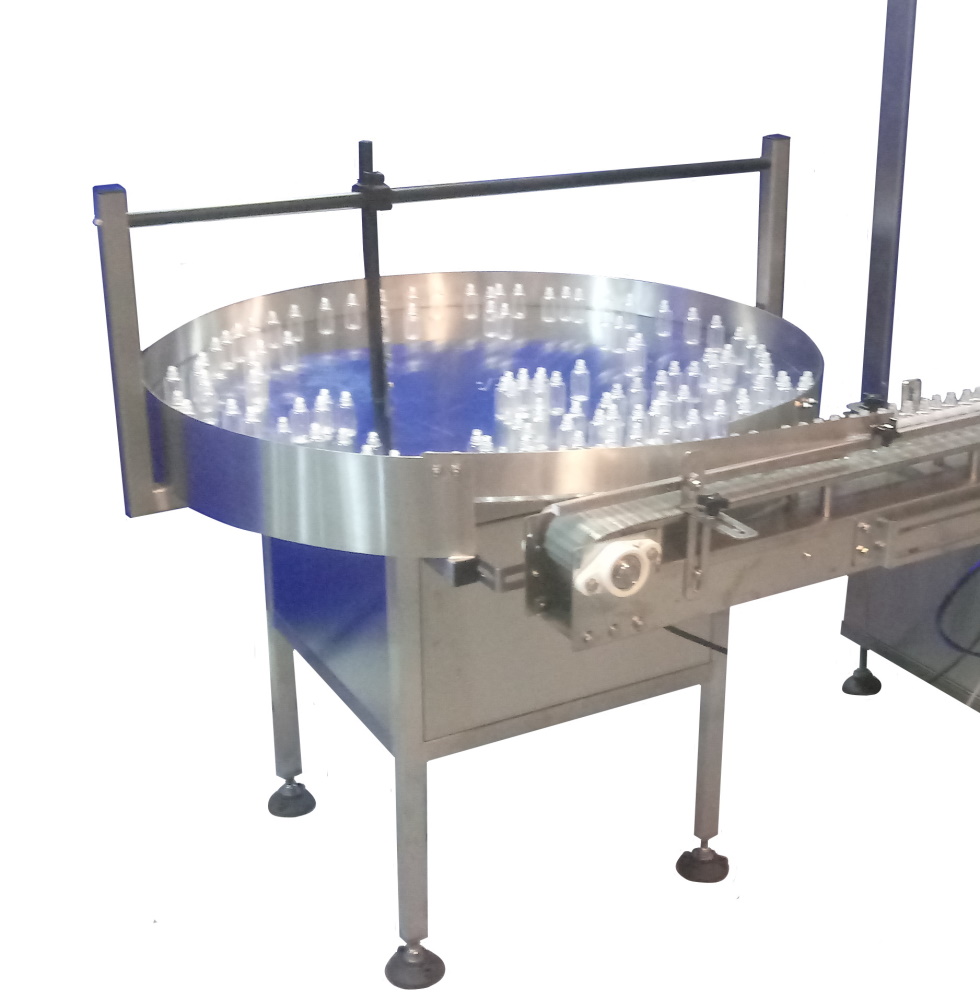

- Turntables for container loading and product accumulation;

- A sanitary power conveyor system to move products through the packaging process.

This typical pharmaceutical and nutraceutical packaging line will not be ideal for every application. A variety of filling and capping equipment is available to meet the individual needs of each individual product.

In addition, the packaging line can expand to include other packaging equipment. Container cleaning equipment, including rinsing machines and bottle vacuums, remove dust and debris from bottles prior to the filling process. The container cleaning equipment helps keep the packaging process sanitary as well. Other packaging equipment can include, but is not limited to, an induction sealer for tamper evident seals, an automatic labeler to quickly and consistently apply labels to the containers, and/or a coder to print expiration dates, batch numbers and more on the container.

For questions regarding pharmaceutical and nutraceutical packaging equipment, call a Packaging Specialist at Liquid Packaging Solutions today at:

1-888-393-3693

The Automatic Spindle Capper from Liquid Packaging Solutions is ideal for almost any packaging project using screw-on, or continuous thread, type closures. Automatic spindle capping machinery provides continuous capping for a wide variety of cap sizes, cap types, ...

This accumulating turntable is manufactured with a stainless steel frame and disc for added durability. The turntable can be used at any point on a packaging system to accumulate product. Turntable tops are available in a range of sizes to accomodate va...

The Automatic Pump Filler from Liquid Packaging Solutions is ideal for highly viscous products and products with particulates. These automatic liquid fillers will include one pump for each fill head and are manufactured to be a part of a complete automated inline ...

This loading turntable is manufactured with a stainless steel frame for added durability. The stainless steel disc is available in a range of diameters to load products onto a conveyor system at any point in a packaging line.

The Automatic Air Rinser and Bottle Vacuum uses dual action nozzles to first blow air into a container to dislodge dust and debris and then vacuum the dust and debris from the inside of the container. This air rinsing bottle vacuum also moves containers through a ...

The stainless steel sanitary style power conveyor from Liquid Packaging Solutions is manufactured with a raised belt and an upside down U-shaped design for protection against spills and easy cleanup. Sanitary style power conveyors are ideal for food grade and dair...

Semi-automatic air rinsers are an ideal container cleaning option for a number of industries with low to medium bottle cleaning requirements. The operator of the air rinser will place and remove bottles with each cycle, activating the cycle through the use of a fo...

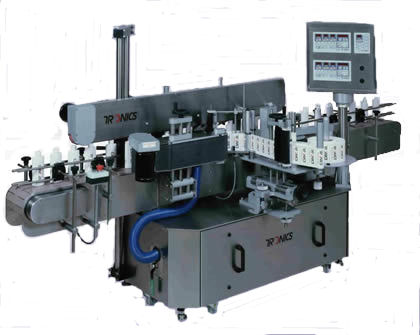

Automatic pressure sensitive front/back and wrap labelers are ideal for facilities labeling a wide variety of containers in a different number of formats. This automatic bottle labeler can also be custom manufactured to apply three panel labels and other unique la...

An automatic, inline packaging system for thick products in the Pharmaceutical and Nutraceutical Industry, including equipment to rinse, fill, cap and label product.

An automatic, inline packaging system for thin products in the Pharmaceutical and Nutraceutical Industry, including equipment to rinse, fill, cap and label product.

A tabletop packaging system for the Pharma and Nutra Industry, including a combination of machinery to rinse, fill, cap and label product.