Oils and Lubricants

Oils and lubricants can range in viscosity from very low to very high, which in turn means the packaging machinery used for the multitude of items in this industry will vary widely as well. For example, when filling an oil or lubricant, an overflow filling machine might be used for products in clear containers that require a consistent, level fill. On the other hand, a pump or piston filling machine may be used for thicker, more viscous oils and lubricants. Liquid Packaging Solutions will manufacture the ideal packaging equipment for your oil or lubricant.

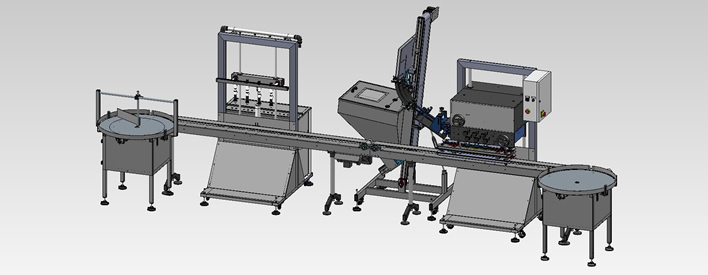

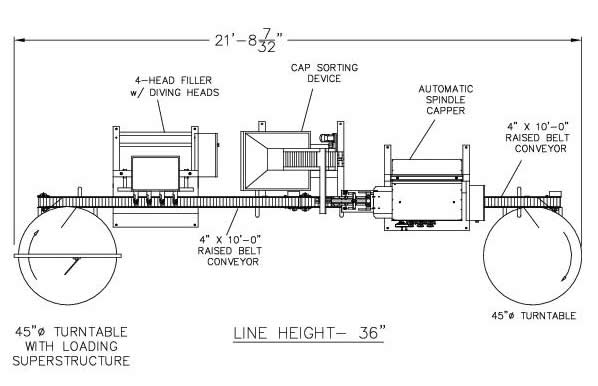

A typical packaging line for oils or lubricants is shown below:

This system includes:

- An overflow filler for consistent, level filling;

- A spindle capping machine for continuous container capping;

- Turntables for container loading and product accumulation;

- A power conveyor system to move containers through the packaging phases.

This typical oil and lubricant packaging system will not be ideal for every application. As noted above, the overflow filler may be replaced by a piston or pump filler for filling thicker liquids. A gravity filler may also be used for time based filling applications. Packaging systems for oils and lubricants can be manufactured as fully automated systems for high production rates or as manual or tabletop packaging systems for start up companies or special product runs.

Additional equipment can always be added to an oil and lubricant packaging system. This additional equipment may include an unscramber for added automation, an automatic labeler for quick application of the product label or even a box erecting machine to create cartons for packing the product. Each complete oil and lubricant packaging system can be tailored to the individual needs of each customer and product.

For questions regarding the packaging of oil and lubricants, including the correct filling machine for your product, contact a Packaging Specialist at Liquid Packaging Solutions toll free at:

1-888-393-3693

The Automatic Spindle Capper from Liquid Packaging Solutions is ideal for almost any packaging project using screw-on, or continuous thread, type closures. Automatic spindle capping machinery provides continuous capping for a wide variety of cap sizes, cap types, ...

Automatic Overflow Fillers from Liquid Packaging Solutions are ideal for thin to medium viscosity liquid products, including products that are "foamy" by nature. The Automatic Overflow Filling Machine is manufactured to be a part of a complete, automated inli...

Semi-automatic air rinsers are an ideal container cleaning option for a number of industries with low to medium bottle cleaning requirements. The operator of the air rinser will place and remove bottles with each cycle, activating the cycle through the use of a fo...

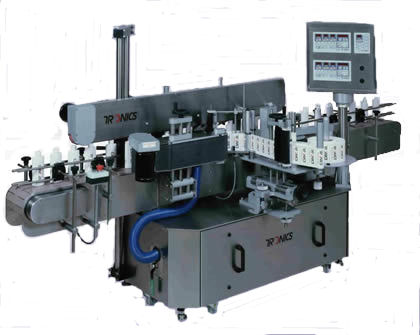

Automatic pressure sensitive front/back and wrap labelers are ideal for facilities labeling a wide variety of containers in a different number of formats. This automatic bottle labeler can also be custom manufactured to apply three panel labels and other unique la...

Low profile power conveyors are manufactured by Liquid Packaging Solutions using anodized aluminum for increased corrosion and wear resistance. Low profile refers to the short distance from the bottom of the belt conveyor frame to the top of the conveyor belt...

An automatic, inline packaging system for thick Oils and Lubricants, including equipment to fill, cap and label product.

An automatic, inline packaging system for Oils and Lubricants, including equipment to fill, cap and label product.

A tabletop packaging system for Oils and Lubricants, including a combination of machinery to fill, cap and label product.