Bottled Water

Liquid Packaging Solutions offers a wide variety of packaging machines and packaging experience to the bottled water industry. LPS has designed bottled water plants and manufactured bottled water packaging machinery for companies across the country and around the world.

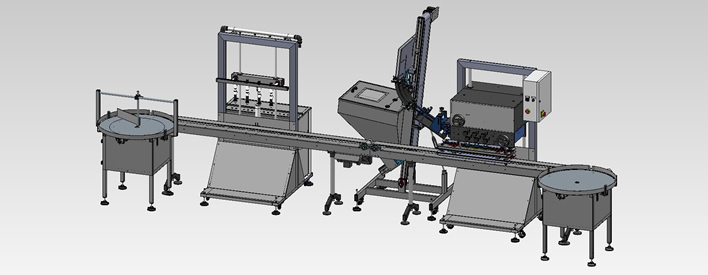

A typical bottled water plant would include a packaging line like the one shown below:

This system includes:

- An overflow filler for consistent, level fills;

- A spindle capping machine for continous capping of containers;

- Turntables for container loading and product accumulation;

- A power conveyor system for moving product through the packaging line.

Of course, this typical bottled water packaging line will not be ideal for every application. A variety of filling and capping equipment is available for bottled water applications. Additional equipment, such as automatic rinsers for container cleaning, bottle unscramblers to replace the loading turntable, an automatic labeler, an induction sealer, or even a pallet wrapper can be added to the bottled water line to meet individual and specific packaging line needs.

Unique applications also require unique designs. LPS manufactured a portable bottled water system by installing a horseshoe type rinsing, filling, capping, and labeling system into a trailer, allowing bottled water to reach the areas where it is most needed. LPS has also manufactured manual and tabletop bottled water systems for start up bottled water companies or lower production facilities.

For questions regarding bottled water equipment, including rinsers, fillers, cappers and more, contact a Packaging Specialist at Liquid Packaging Solutions toll free today at:

1-888-393-3693

The Automatic Spindle Capper from Liquid Packaging Solutions is ideal for almost any packaging project using screw-on, or continuous thread, type closures. Automatic spindle capping machinery provides continuous capping for a wide variety of cap sizes, cap types, ...

Automatic Overflow Fillers from Liquid Packaging Solutions are ideal for thin to medium viscosity liquid products, including products that are "foamy" by nature. The Automatic Overflow Filling Machine is manufactured to be a part of a complete, automated inli...

Wrap labelers are used to apply a wrap around label to containers as small as 5 ml as well as those large enough to circle 10 gallon pails. Simple to use centralized controls and an LCD display on this bottle labeler make changeover from one container to another q...

The automatic inverting air rinser allows for continuous container cleaning on an inline packaging system. The air rinser inverts containers over a basin and rinses the inside of individual containers with a blast of compressed air or other air supply. PLC c...

Semi-automatic air rinsers are an ideal container cleaning option for a number of industries with low to medium bottle cleaning requirements. The operator of the air rinser will place and remove bottles with each cycle, activating the cycle through the use of a fo...

Low profile power conveyors are manufactured by Liquid Packaging Solutions using anodized aluminum for increased corrosion and wear resistance. Low profile refers to the short distance from the bottom of the belt conveyor frame to the top of the conveyor belt...

An automatic, inline packaging system for the Bottled Water Industry, including equipment to fill, cap and label products.

A tabletop packaging system for the Bottled Water Industry, including a combination of machinery to fill, cap and label product.